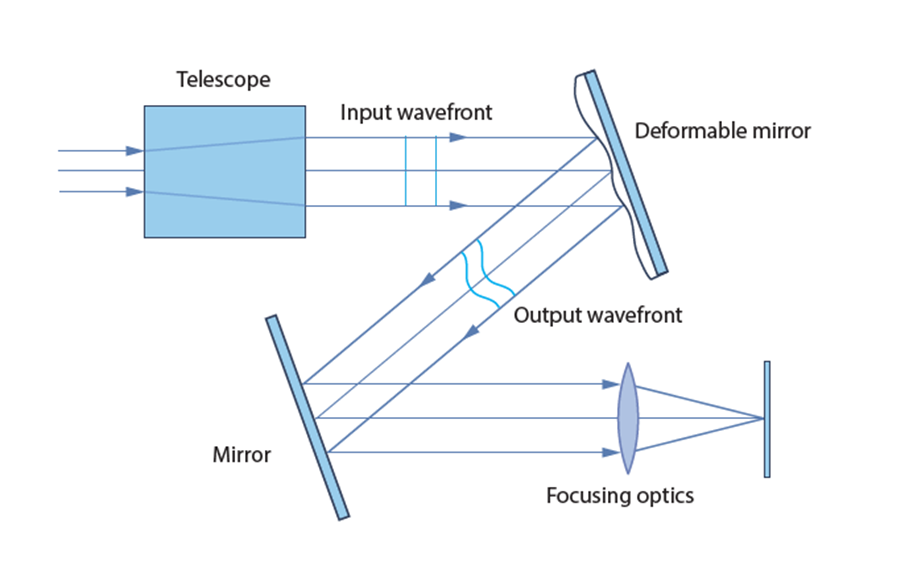

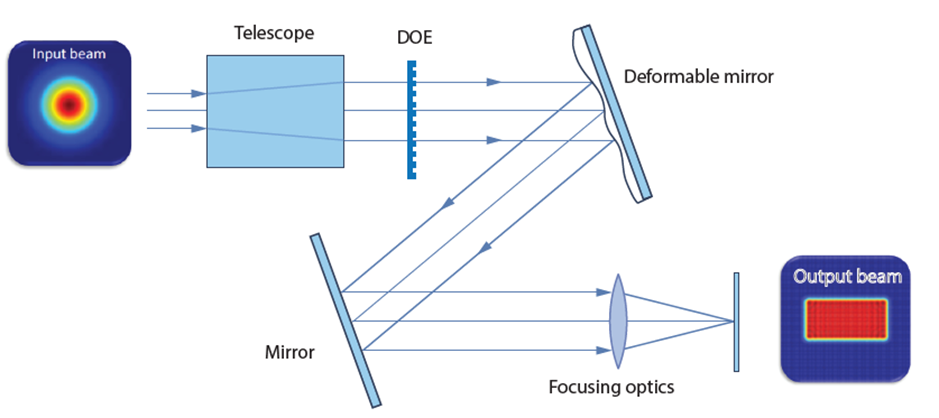

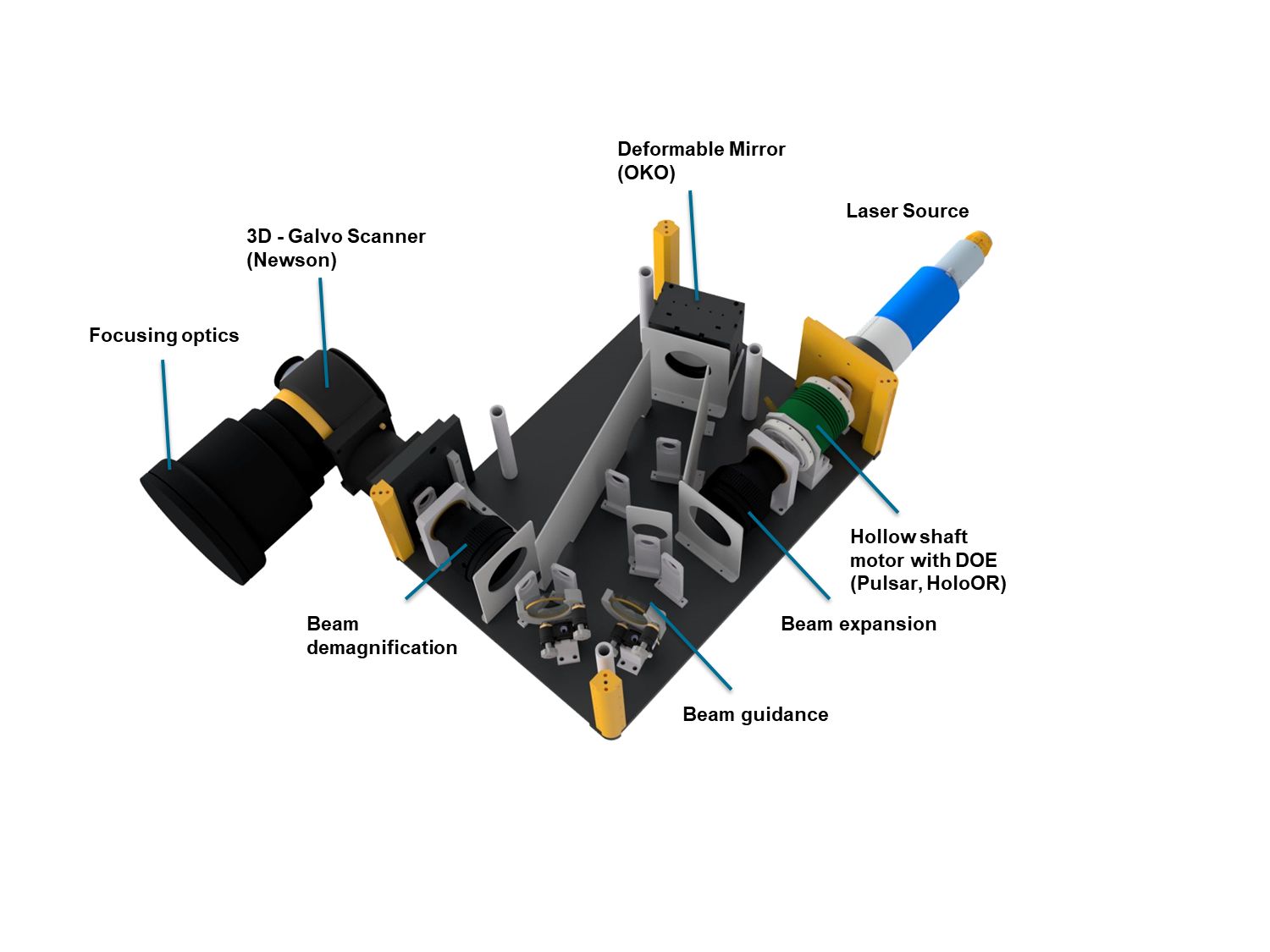

The beam size on the mirror was found to be a crucial parameter for the quality of the realised intensity distributions. If the beam is too small, too few of the actuators of the mirror are effectively used for beam shaping. If the beam is too large, the lowered actuator density at the edge of the mirror and reduces the beam shaping capabilities and diffraction effects heavily impact the result.

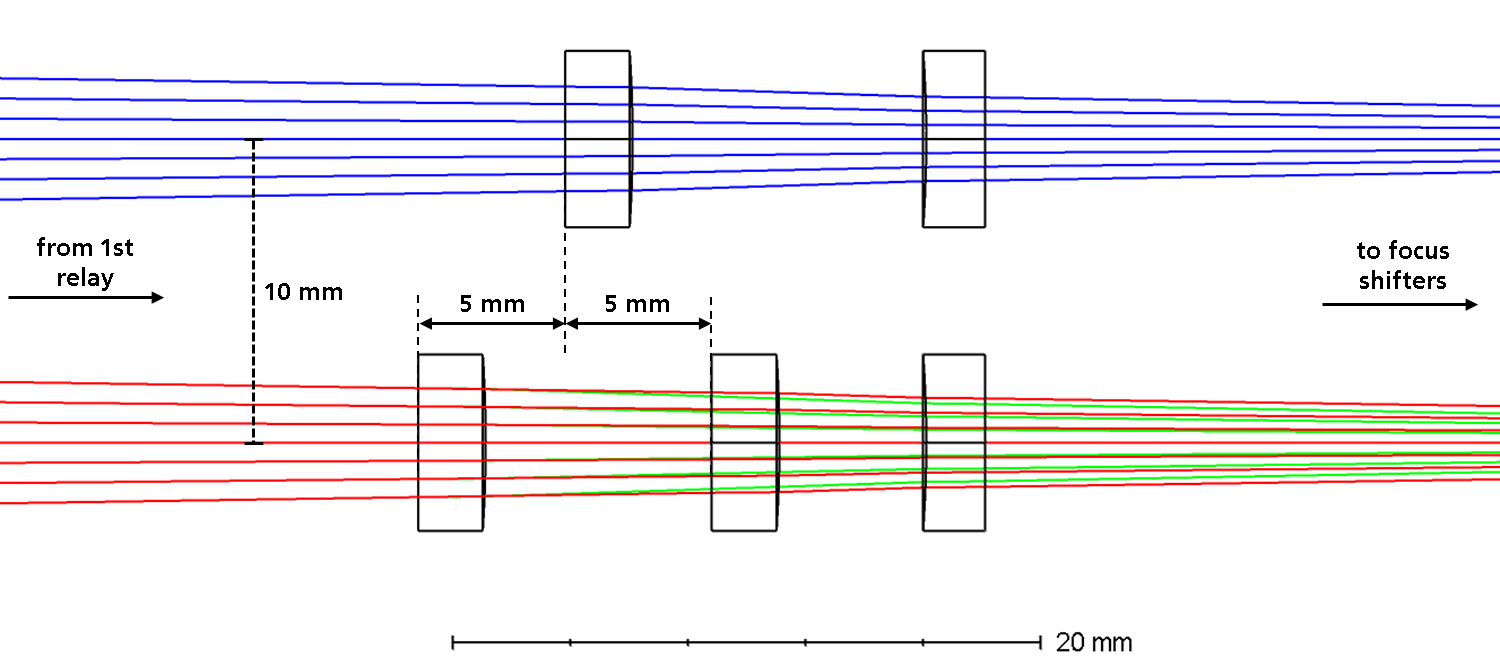

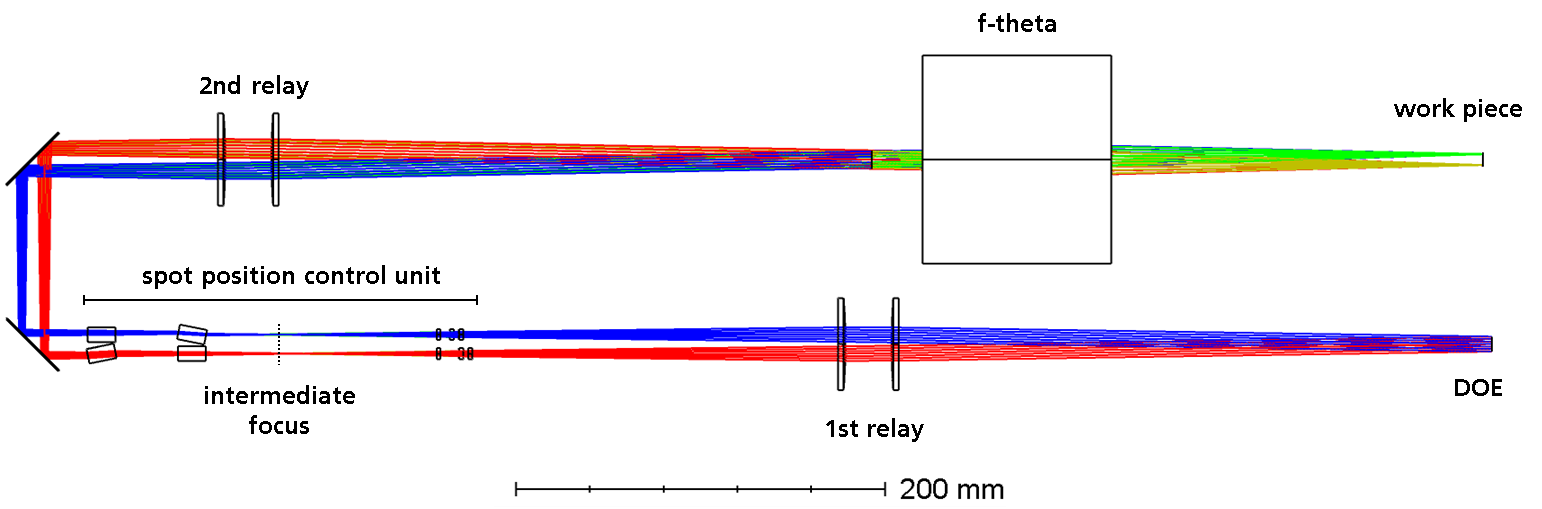

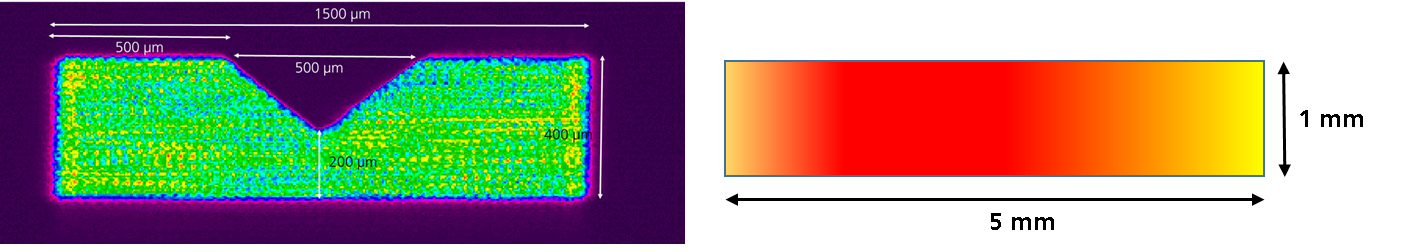

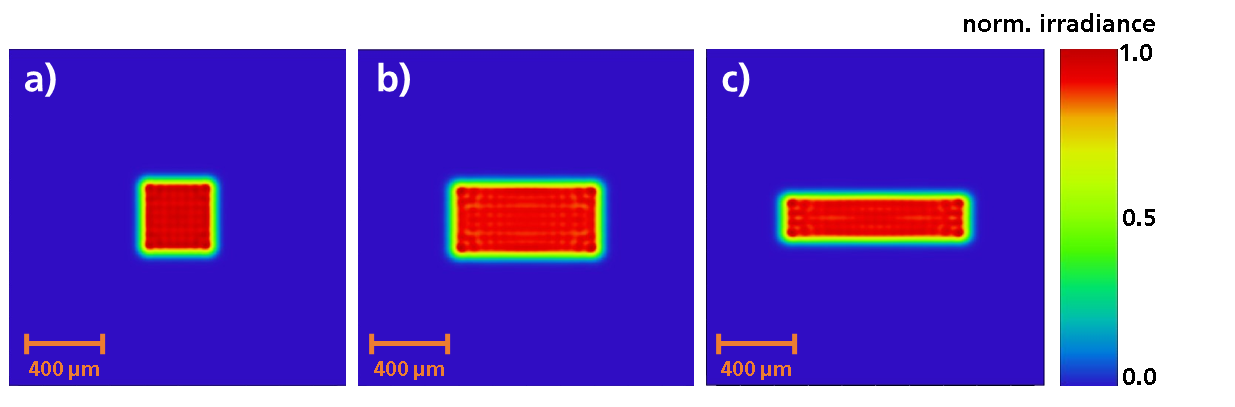

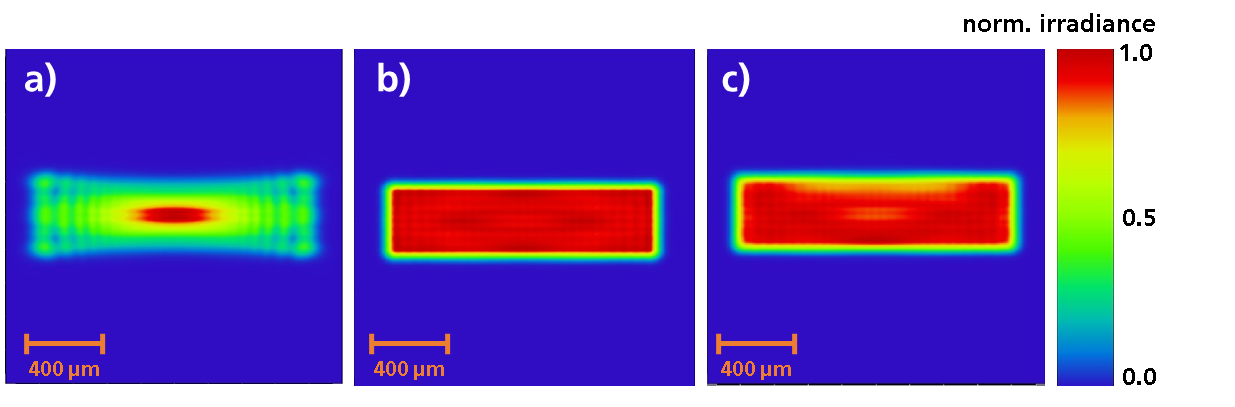

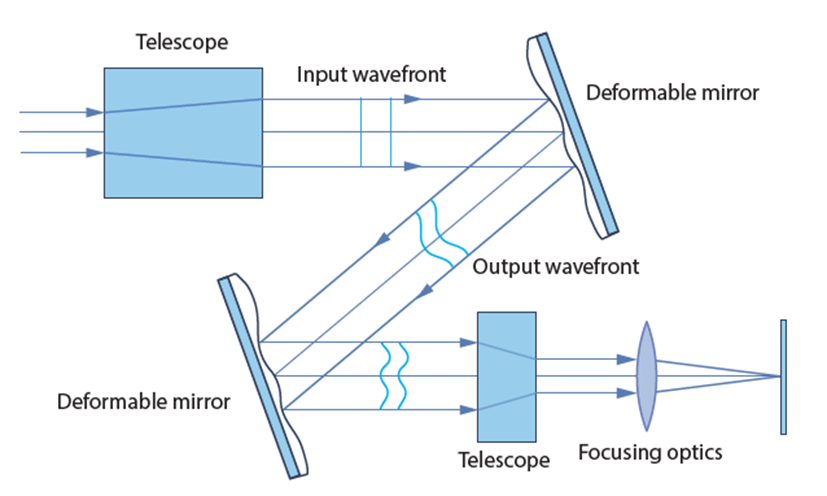

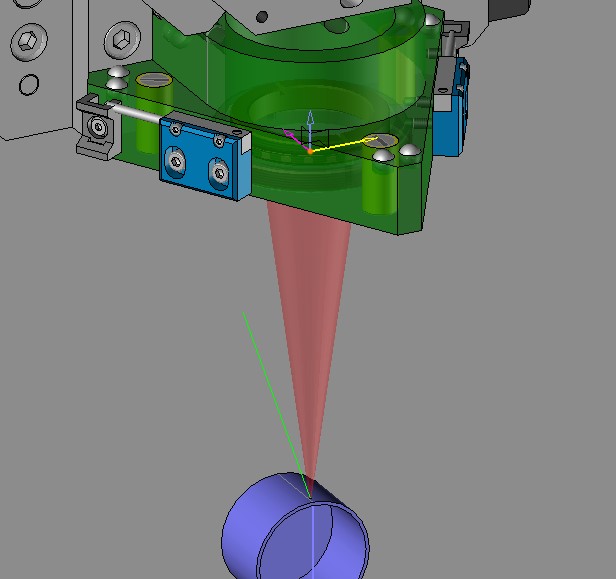

As seen in Figure 3, the PDM is well suited to generate almost diffraction limited rectangular tophats of various sizes and aspect ratios. The orientation of the rectangles is arbitrary for the beam shaping with the deformable mirror but for consistency and better comparability, all shown rectangles are orientated in the same way. Note that shaping a 1500 µm x 400 µm rectangle (target distribution for laser polishing) in the focal plane of the focusing optics is not possible with this concept as shown in Figure 5 a). The required amplitude of the phase change is too large for the PDM to realise. As only the total size of the intensity distribution and not the aspect ratio is the problem (as a 4:1 aspect ratio is demonstrated to work in Figure 3 c)) one can solve this drawback by adding another telescope in front of the focusing lens (cf. sec. 1.4). Another solution is to not work within the focal plane of the focusing optics but in front of it (or behind it). As the undistorted spot is already larger there, less phase change is required to achieve the target intensity distribution (cf. Figure 5 b)). However, the realisation of a 5 mm x 1 mm rectangle (target distribution for thin film processing) is not possible with the initial concept. And while shaping a 1500 µm x 400 µm rectangular tophat is possible with this concept, the PDM is not able to produce the desired cutoff as shown in Figure 1 (cf. Figure 5 c)). Thus, an alternative concept had to be developed.

Note that most simulations in the feasibility studies were performed with a focal length of the F-Theta lens of 450 mm as this is a typical focal length already used in laser polishing applications at FHG-ILT. Such a long focal length also allows for better beam shaping results as the required gradient of the deformable mirror surface for a given intensity distribution is inversely proportional to the focal length of the objective.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT