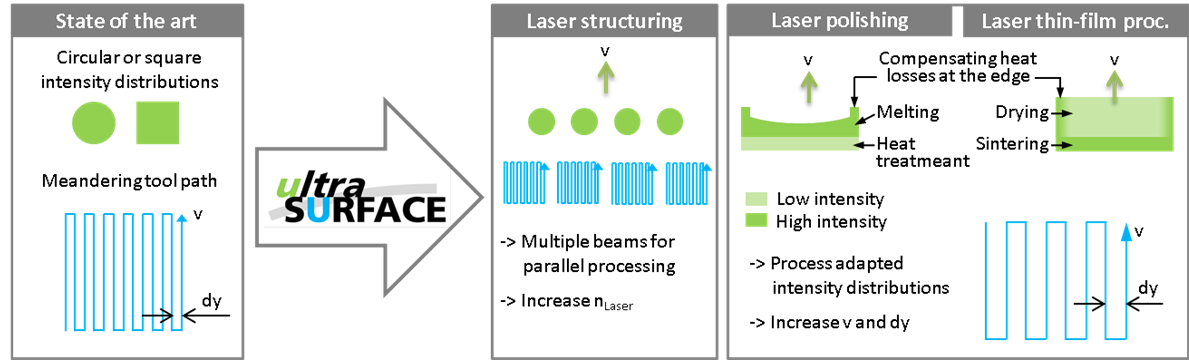

Laser structuring can achieve small structures on a sub-millimetre down to micrometre scale (Figure 1a). In particular, ultra-short pulsed lasers provide unique possibilities to manufacture smallest structures with highest demands on accuracy and quality. But for many applications the low throughput is still limiting this technique to the processing of moulding tools rather than the direct processing of the work piece itself.

Laser polishing is based on remelting a thin surface layer and smoothing the surface due to the surface tension. Starting from a metallic surface with an initial roughness of Ra = 1 - 10 μm laser polishing can achieve a roughness of Ra = 0.1 - 0.5 μm (depending on the material and its homogeneity). First industrial applications already show the potential of this new technology (Figure 1b) but there are still limitations which are preventing a broad industrial impact. The main limitations are a relatively low throughput and an enormous effort to establish this technique for new materials and 3D work pieces.

Laser thin-film processing is a powerful tool for improving the performance of technical components e.g. regarding wear, corrosion or electrical conductivity (Figure 1c). Thin film processing is often a 2-step process involving the deposition of the film followed by a heat treatment. For heat treatment lasers represent a versatile alternative to conventional methods and enable processing of thermally sensitive substrates. Especially the ability to treat layers locally and selectively opens up new possibilities. Nevertheless, in many fields of application this technique requires long processing times and is not adaptable for complex three-dimensional components yet.

In summary in many applications these laser based surface processing techniques already achieve highest precision and quality, but often the throughput is limiting the industrial capability.

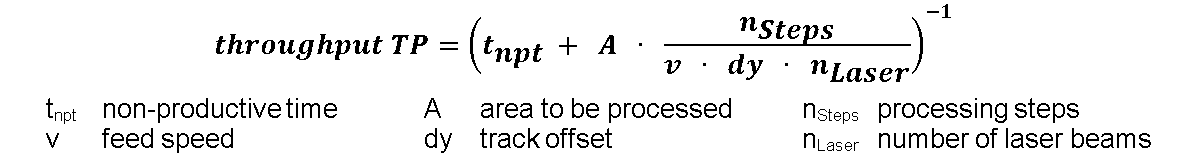

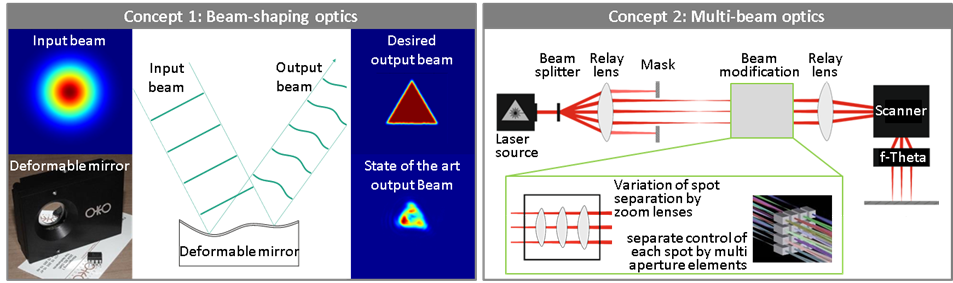

State of the art for these and many other applications in laser surface processing is the utilization of one round laser beam (Figure 2 left). For processing in a meandering pattern the throughput TP (parts per time) can be calculated as

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT